Cutting Dies

Die Manufacturing

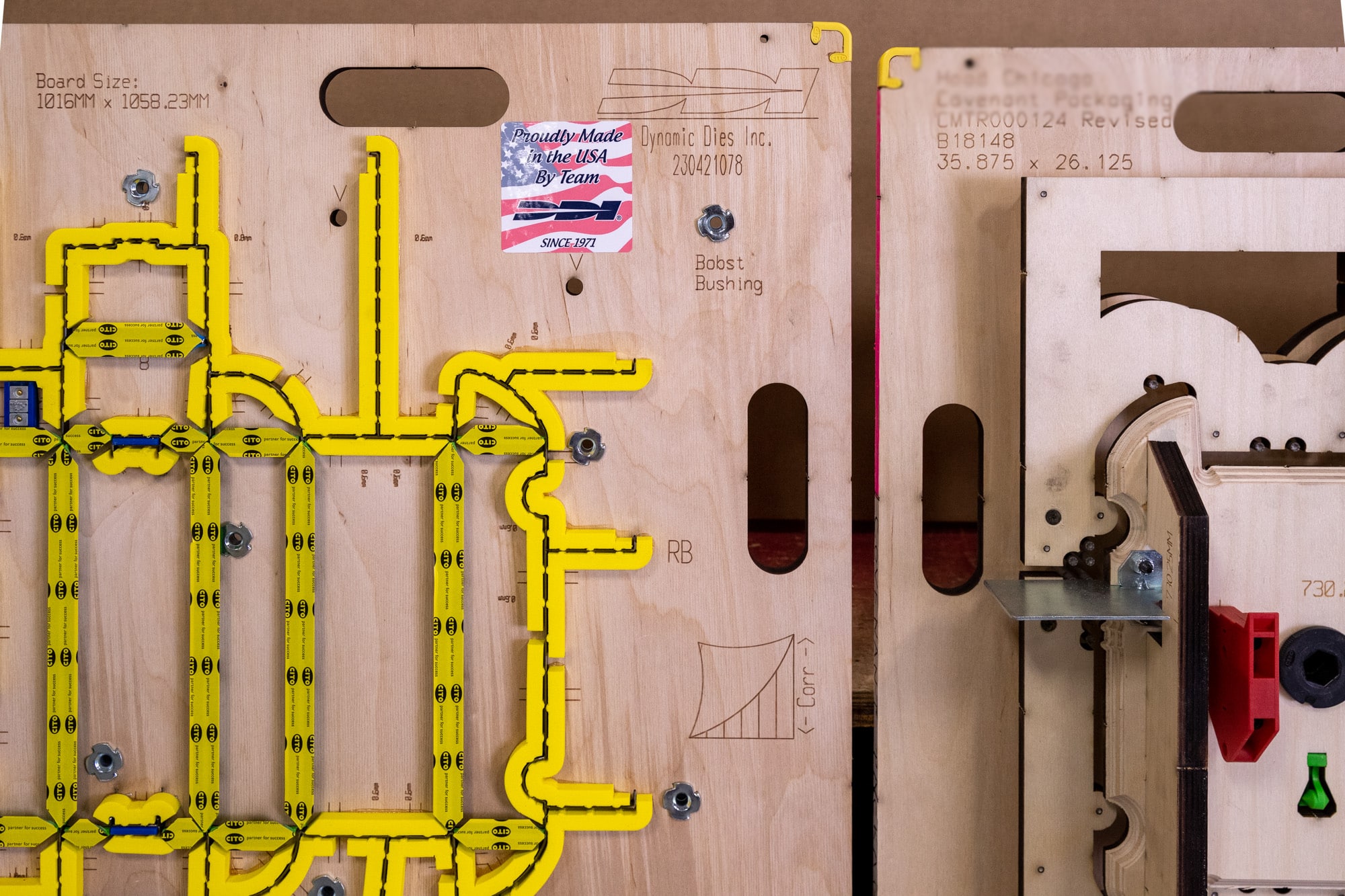

When you need specialized tools to produce corrugated and other packaging materials, Dynamic Dies is your cutting die manufacturing expert. We do more than make cutting dies. As a tooling supplier, we also provide the technical expertise, customization and support to deliver the cutting die you need for your project. Our custom dies for POP/POS displays, retail-ready packaging and corrugated boxes are specially designed to fit your needs.

Die Making

Steel rule die cutting is constantly evolving. Delivering sophisticated steel rule cutting dies in days—not weeks—requires highly skilled technicians teamed with state-of-the-art, specialized automation. Dynamic Dies understands your need for speed and accuracy. With four full-service facilities throughout Ohio, Pennsylvania and Indiana, we are equipped to accommodate your die making needs. We follow stringent, ISO-level manufacturing standards with a PEC1 philosophy of prevention, elimination, conformance and less than 1% cost quality. This means our cutting dies are consistent and guaranteed to perform for even the most complex projects.

Cutting Dies for Productivity and Performance

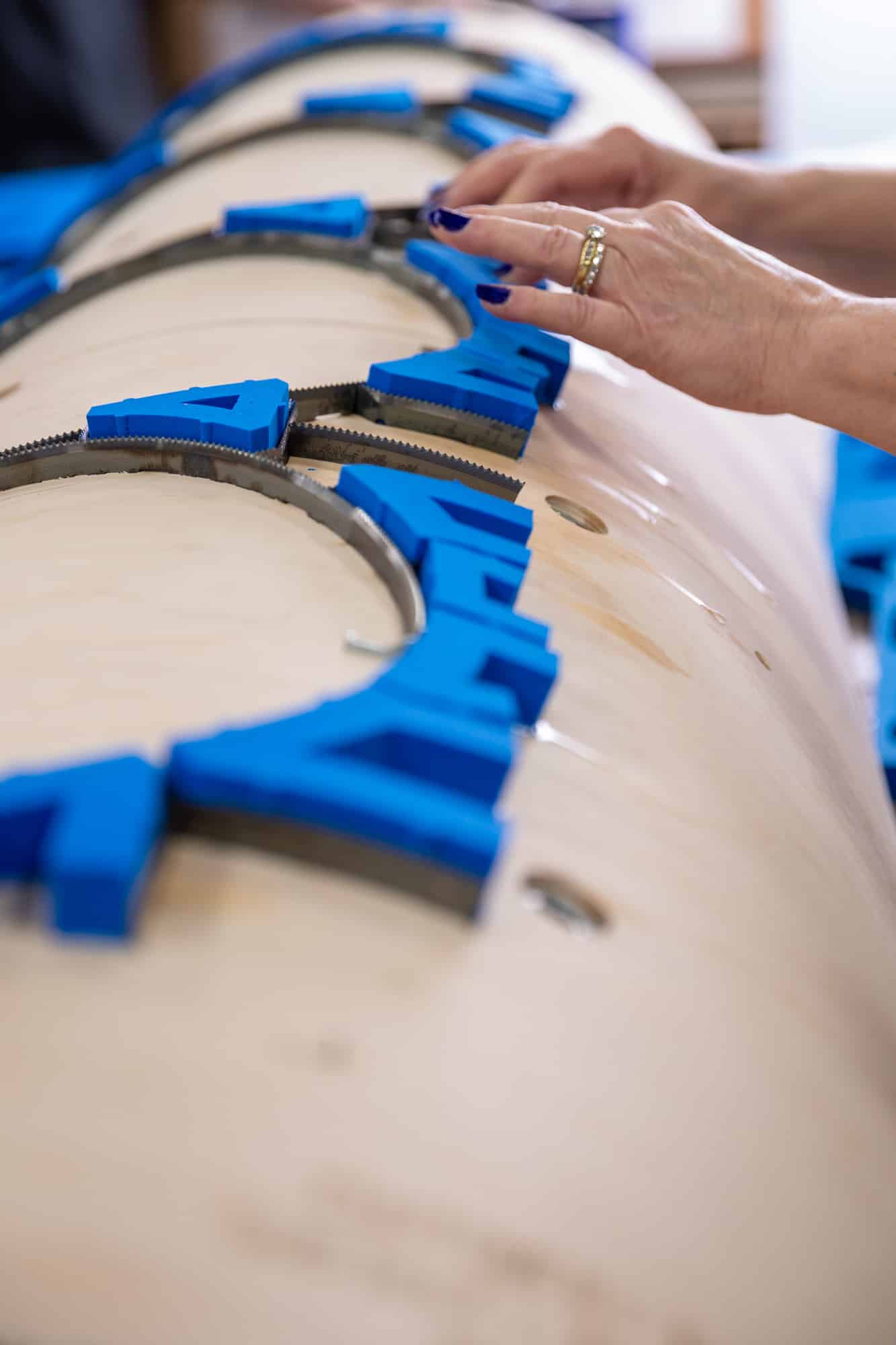

Flat, Rotary and Specialty Cutting Dies

Our rotary steel rule cutting dies for corrugated packaging come in 7” inside diameter (ID) to 26.5” ID.

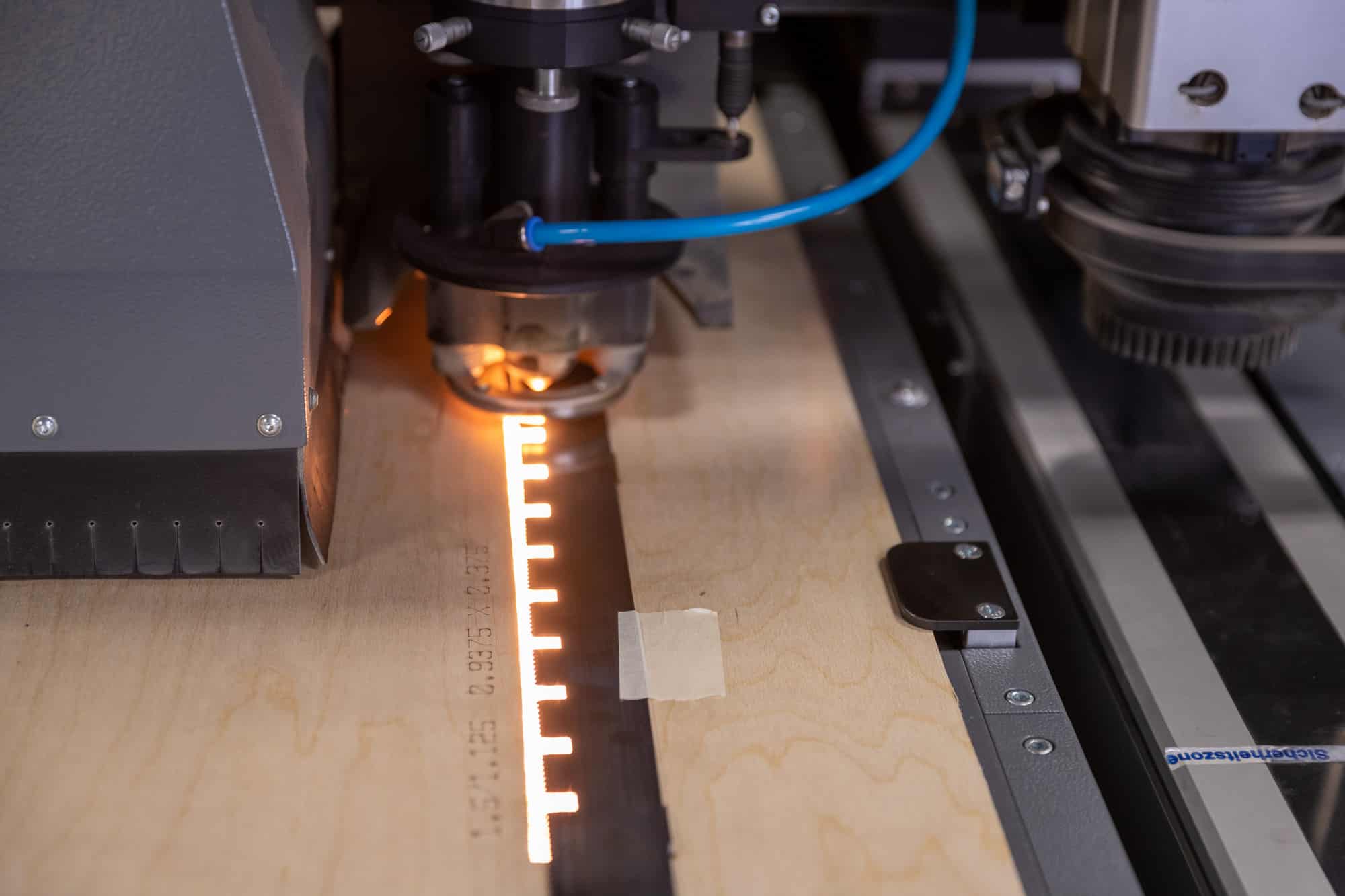

Our manufacturing process includes laser-cutting and CNC automation for accuracy, consistency and high-speed production. Aside from corrugated packaging, our high-performance cutting dies can cut a range of materials, including:

- Automotive die-cut parts

- Carpet

- Foam products

- Paper

- Plastic corrugated material

Auto Bending for Precision Die Cutting

Auto bending is a process in die cutting that automates the rule bending process as opposed to manually bending the rule. With automated rule bending equipment, Dynamic Dies can process 2 point to 6 point rule from 0.937” to 2.00” high. Versatility and automation expands our product offerings and allows us to complete complex cutting die orders.

Why is auto bending important? It’s especially effective for cutting and creasing materials with a high level of accuracy. Plus, it increases production speed, reduces waste and results in a more productive, cost-effective process.